Life gets overwhelming sometimes. So much so that most people hardly have the time to make a home-cooked meal every day. On the flip side, for some, cooking is not even something they enjoy, to begin with. In both instances, pre-cooked meals are a lifesaver.

That said, cooked food is a sensitive product that requires careful preservation until it reaches customers. So, as a ready-to-eat food vendor, how do you make this happen? The answer, in brief, lies in choosing the right packaging. Let’s explore some flexible packaging ideas that will keep your cooked food servings fresh and have customers coming back.

Table of Contents

LogosPack

Company Details

- Location: Fushan, China

- Company type: Manufacturing and Packaging

- Year founded: 2005

- Number of employees: -

- Key Products: Flexible Packaging

Other products include:

LogosPack was established in 2005 amid growing demand for high-quality flexible packaging products in China and beyond. To plug that deficit, the company quickly established itself as the number one maker of plastic materials in Fushan, and within no time, they were getting orders from other parts of the vast Asian nation.

Today, LogosPack handles even international flexible packaging supplier exports and continues to create high quality recycled product packaging like spout pouches that are used in the food and beverage industries, big pharma, chemical industries, among many others.

Retort Pouches

Retort pouches are multilayered and designed for sterile food packaging. The layers are often made of aluminum foil and polyethylene. They were initially invented for MRE army rations but have since become a mainstay in the retail food industry. They can be used to package liquid, semi-solid and solid foods without the need for refrigeration.

This type of packaging would be ideal for foods that you anticipated may not be consumed immediately. Ready-to-eat meals sold at supermarkets, for example, would be good candidates for retort pouches as they may require a longer shelf-life. Cooked meals for passengers on planes, road trips, and even trains can also be packaged this way to avoid destabilization of flavors and contamination.

It is, nevertheless, important that you make an effort to make your packaging impressive. Contrary to wise adages, consumers do judge food by its packaging. Mouth-watering pictures of the food in the pouch would go a long way in attracting buyers. An established retort pouch manufacturer should be able to offer you custom printing services.

Foil Pouches

Source: Pinterest

As the name suggests, foil pouches are made using aluminum foil in a quad seal pouch design. For display purposes, one side of the pouch can be lined with a transparent material such that the food contents are visible.

The more layers a quad seal foil pouch has the higher its oxygen and moisture barrier. It can thus store food longer although not as long as a retort pouch can. Due to this, it advisable to use them for less perishable foods or products that will sit on a shelf for relatively short periods. Embellishing or branding foil pouches might be easier if you use sticker labels. Nonetheless, you could customize them with extra features such as a ziplock for secondary sealing.

Kraft Paper Bags

Kraft paper is made from wood pulp. It is a very resilient type of paper that is absorbent, food-safe, and does not tear easily. The best part? Kraft paper bags are compostable packaging and so by using them, your company would be doing its bit in ensuring sustainability.

If you run a deli, a restaurant, or a bakery, kraft paper bags would be a great packaging option for you. They hold fish and chips just as well as they keep pastries fresh and soft. Their absorbency handles grease and steam from food quite well so you would not have to worry about the bag disintegrating as customers receive their orders.

Kraft paper bags are often designed as flat bottom gusset bags and remain intact during printing. So, for that extra touch of customer service, consider branding your packaging. If you are wary of issues such as food tampering, you could also have them fitted with closures such as a tin tie.

Film Wraps

Roll stock films can best be described as they retail quality versions of cling film and aluminum foil. Retail quality here meaning that packaging film wraps are made using a higher grade of plastic or aluminum and do not tear easily.

Film wraps would be ideal for refrigerated food products, foods that have low perishability or take-out that does not require a long shelf-life. Examples of such foods include processed meats or stir fry vegetables. It is also possible to use film wrap on its own or in conjunction with rigid packaging options such as plastic trays. This combination tends to make overall handling of the food much easier even for customers as they warm the food at home.

On branding, you could opt to go for printed film wraps with product details, decorative graphics, and your brand name. Alternatively, especially if you are using clear film, consider asking your packaging supplier to make appropriate stick-on labels.

Flow Packs

Source: embalagemmarca.com.br

Flow packs get their name from how they are manufactured; in a flow sequence where they are cut into individual sachets. They are made of different kinds of paper depending on the product they will be used to package. Often, for cooked food products the interior part of a flow pack is lined with foil lamination to increase its barrier capabilities. This in turn improves food preservation as the extra layers shield the food from oxygenation and moisture.

Single-portion cooked meals like lasagna slices or salads are the best match for flow packs. For structure, a small tray may be inserted into the flow pack to hold the food. You could also consult your flexible packaging manufacturer on customization options like a clear window or custom printing.

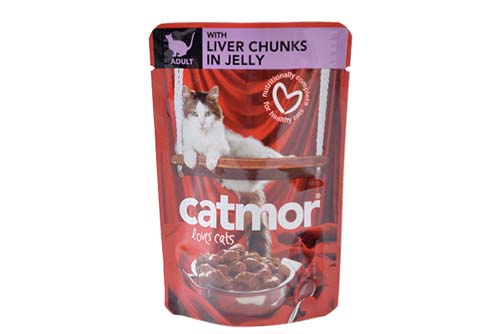

Flow packs are sometimes also used as packaging for cooked pet food. This is because they make it easy for pet owners to serve just the right amount without having to measure.

Form to Fill Packaging

Source: Pinterest

Form to fill refers to packaging that you would receive from your packaging supplier as flat sheets of paper. They should preferably be made of biodegradable paper like Kraft or PLA paper and can have marked folding sections. Whenever you need to package food for a customer, you would form the paper into box packaging by folding along the marked lines. Shrinkwrap also falls in this category.

Pastries, burgers, pizza are some examples of cooked foods that are packaged in this manner. Shrinkwrap or film would be ideal for industrial-scale food packaging and would ideally be used with the aid of a form-fill-seal machine.

Waxing Paper

Source: Pinterest

Waxing paper is a staple in bakery but it is equally a great cooked food packaging solution. It is a bit more absorbent than ordinary paper, safe for food, and does not tear easily due to the wax coating.

From baked goods, sandwiches, burgers, and even fries, the packaging applications of waxing paper are quite vast. If you are in the fast-food business or run a deli, this would certainly be worth looking into. Further, instead of plain old waxing paper, you can customize yours with interesting prints that customers can associate with your brand.

Conclusion

When it comes to food packaging, hygiene standards and food safety are non-negotiable. This is why choosing the right cooked food packaging materials supplier is just as important as choosing the right packaging method.

Aim for brands that use materials certified by regulatory authorities like the FDA and maintain proper sterile conditions during manufacturing. Additional services such as branding, decorating, and customizing designs are equally a significant plus. More so because cooked food should be well-labeled complete with manufacturing and expiry dates.