Stand-up pouches are one of the most popular flexible packaging methods. They deliver a great experience for customers and are way more affordable than most rigid packaging alternatives. As a product manufacturer, they would also make marketing easy as they have ample surface area for branding and product decoration.

As you order stand-up pouches for your products, it is important that you understand your branding options. There are different ways to print on stand-up pouches depending on the images you wish to have and other factors like budget. Below, we explore the 3 key methods and how to pick the right one for your packaging.

Table of Contents

LogosPack

Company Details

- Location: Fushan, China

- Company type: Manufacturing and Packaging

- Year founded: 2005

- Number of employees: -

- Key Products: Flexible Packaging

Other products include:

LogosPack was established in 2005 amid growing demand for high-quality flexible packaging products in China and beyond. To plug that deficit, the company quickly established itself as the number one maker of plastic materials in Fushan, and within no time, they were getting orders from other parts of the vast Asian nation.

Today, LogosPack handles even international flexible packaging supplier exports and continues to create high quality recycled product packaging like spout pouches that are used in the food and beverage industries, big pharma, chemical industries, among many others.

Digital Printing

Source: epson.presspage.com

Digital printing is done using a digital printing machine which has a distinct design from analog printers. With a digital printing machine, there is no changing of plates and hence the printing process is continuous and easy. Moreover, it can print multiple colors in one cycle as opposed to having to run the stand-up pouch several times for each color to be printed separately.

Branding stand-up pouches using a digital printing machine occurs in a series of steps. First, the sketch of the design to be printed would either be sketched by hand or drawn on a computer. Once it is complete and the colors have been chosen, the pouch would be fed into the printer and the image would be printed onto it. Only one print can be done at a time.

Pros:

- Digital printing produces quality images

- You can work with a variety of colors

- It prints both opaque and transparent stand-up pouches well

- It is an easy process that does not require a full industrial-scale set-up

- Customizing designs is fast and it is possible to stop the process and correct any errors

Cons:

Flexography

Source: keralapool

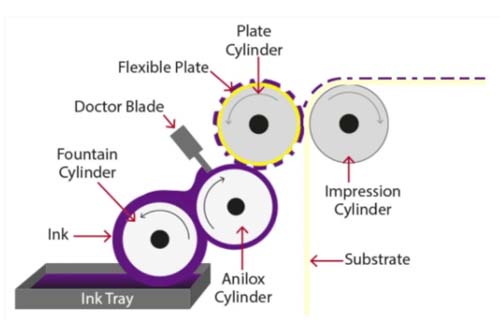

Flexography is a slightly more complex operation compared to digital printing. It is done using a printing press machine fitted with a flexible rubber plate. The process takes place as follows:

- The preferred images or graphic designs are sketched and agreed upon

- Using a plastic-molding device, the images are engraved into the flexible rubber plate of the printing press in the form of tiny holes

- Liquid ink is poured onto a rotating ink-dispensing roller

- An automatic blade then shaves off any excess ink on the roller to prevent blotting and dripping

At this point, the stand-up pouch to be printed should be placed on an impression cylinder. This is a flat surface that holds the pouch as the printing occurs.

It is important to note that a flexography printing press has multiple units that each print a single color. As such, to achieve multicolored prints, the stand-up pouch would have to be taken through different printing units until all colors are complete. These colors are known as CMYK colors representing cyan, magenta, yellow, and Key which is black. Further, while this process may seem long and arduous, it is automated and can go by quite fast.

Pros:

- Flexography is an affordable way to print large batches of stand-up pouches

- It uses water-based, acrylic, or aniline inks that dry fast and are safer than oil-based inks that get absorbed in the pouch material

- It is applicable on stand-up pouches made of different materials

- It is safe even when used on stand-up pouches meant for packaging food products

Cons:

- It can be difficult and time-consuming to stop an ongoing flexography print run to make corrections or improvements to the chosen design

- All colors can not be printed in one go

Rotogravure Printing

Source: Pinterest

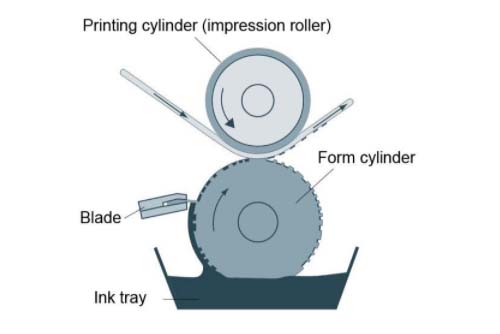

A rotogravure machine uses copper cylinders to impart image designs onto stand-up pouches. It is one of the most popular methods because of the durability and quality of images it delivers. To understand how the process works, perhaps it would be helpful to begin by demystifying its structure.

There are 4 mains parts to a rotogravure machine:

The upper cylinder– is usually designed to resemble a giant size rolling pin. It is engraved with the design of imagery that is to be printed on a stand-up pouch.

The lower cylinder – this too is like a giant rolling pin mounted right below the upper cylinder with only enough room between them for the stand-up pouch to be pulled through.

The doctor blade- this used to shave off any excess ink during the printing process. It also keeps the upper cylinder clean.

The color injector- this is a dispensing mechanism that releases color for the printing process.

Here is how rotogravure printing press works:

- The imagery to be printed on the stand-up pouch is engraved on the upper cylinder. It is then positioned right above the lower cylinder.

- The roll of stand-up pouches to be printed is also loaded on a rolling cylinder

Printing begins.

- The roll of pouches is passed through the small space between the lower and upper cylinder

- The ink injector sprays the lower cylinder with liquid ink

- As both cylinder roll together the upper one imprints the template of the imagery while the lower one imparts color

- The doctor blade scrapes away any excess ink on the cylinders

Due to this structure of operations, a rotogravure printing press comprises multiple printing units for different colors. If your chosen design is multicolored, the pouches would be cycled through multiple printing units until each color is done. Finally, the roll would be cycled through a drying unit and quality inspection.

Pros:

- Rotogravure produces very rich tones of color and vivid images

- It works well on a variety of materials

- It is fast and economical for bulk printing

- Its prints are long-lasting

Cons:

- It requires an industrial scale set up

- The initial cost of purchasing a rotogravure machine can be high

Tips and Considerations When Navigating Stand-up Pouch Printing

Source: Pixabay

It is always a good thing when you have multiple options to choose from. However, it can also make choosing the right method a bit trickier. So, here are some tips to help you navigate the printing process.

- Check for typos and other errors before approving a printing design.

- Ask for samples before the whole batch of stand-up pouches is printed; sometimes the color-matching can be off and some designs do not always look the same when they are finally on paper.

Further, as you choose your preferred mode of printing, consider:

Your budget- digital printing is affordable only for small batches, while flexography can be cheaper than rotogravure.

Value- rotogravure, though a bit pricey, offers great value for bulk printing and also in terms of quality of work.

The quality of the inputs– low-quality inks will make for poor printing but can also be harmful to your products and subsequently your customers. Ensure that the inputs used are up to code.

Conclusion

It is much easier to know what type of printing method to invest in when you understand what each of them has to offer. It equally gives you more control over your operational costs. So, what method will you be asking your stand-up pouch manufacturer to implement on your order?