Source: Pinterest

Contract packaging is a unique process of making and assembling packaging for a product to get it ready for sales on the retail level using a third party company that may have better packaging machinery. The firms that make this kind of packaging can be considered to be an extension of the manufacturer. The main aim is to make the packaging as reliable and presentable as possible.

Table of Contents

The Contract Packaging Process

Source: Pixabay

Co-packing manufacturing goes through a unique process that takes more time and more detailing to create a unique form of packaging. The following are the phases of the co-packing creation process.

Design: Packaging design is the most important part of contract packaging. This is where most of the attention and the funding goes because the main aim of contracting packaging to another party is to make it unique. This phase is handled by a team of designers who come up with a blueprint from scratch. There are a lot of back and forths in this phase between designers and clients until the right packaging is arrived at.

Inventory Management: This is the storage of the product once the packaging has been completed. Once the packaging is received, it again goes through an audit phase and then properly stored.

Printing Components: The company artwork is provided and then added to the packaging. This could be in the form of the logo, the name of the profit, or any other unique artwork that is able to communicate what exactly is inside the packaging.

Production of Packaging Elements: This is the part where other elements of the packaging are added, and they include trays, clamshells, blister packs, among many others. They are the elements that enhance both the appearance and the structural integrity of the packaging.

Assembly: This is the phase where the packaging of the product actually happens. Depending on the packaging, the process can be very complex. Each product has its own sequence of packaging and has a series of accompanying materials like coupons, stickers, and others.

Storage: This is the final stage where the packed product is now stored, awaiting transport to the retailers for sale. The storage conditions depend on the product; some require cold storage, and others can be placed in room temperature conditions.

Why Manufacturers Use Co-Packaging

Source: Pinterest

There are certain reasons why flexible packaging companies would turn to contracting their packaging duties to a third party; some of these reasons include the following.

Contract packers have better machinery and the best designers who are able to focus all their attention and energy on creating the best packaging materials. They have the right knowledge and the skills to pull this off effortlessly.

It is a short term engagement that saves the manufacturer the money they would need to hire a whole department of packagers. By giving that role to a third party, it gives them the freedom to control what they need when they need it.

Contract packagers have in-house resources that allow them to respond to quick changes depending on what the client wants. This is the kind of flexibility that manufacturers would be too pressed with other parts of production for them to deal with the packaging.

Contract packagers have the space to store the finished products and can handle the shipping to retailers directly without having to waste time returning the finished products to the manufacturer first.

Contract Packagers are able to create their own customized machinery that can enhance their ability to get things done. This level of specialization is what makes them a better option for creating packaging materials.

Types of Contract Packaging Solutions

Source: Pinterest

Contract packaging comes in various categories that include the following.

Primary Packaging: This is the kind of packaging that is made by direct contact using liquid and powder as the packaging process is taking part.

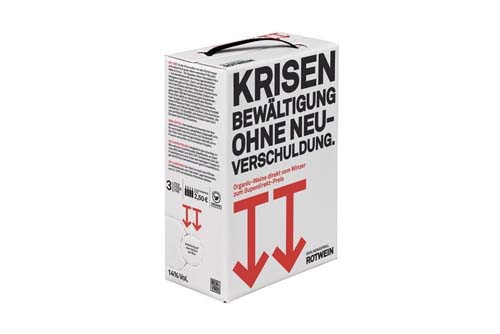

Secondary Packaging: This is where the final assembly of a product that has undergone primary packaging. For example, bag-in-box suppliers where a bag contains the product into another box giving it two layers of packaging.

Hand Assembly: This is the manual assembling of packaging kits, and they include gift boxes, sets, gluing, folding, repackaging, POP displays, among many others.

Contract Filling: This is the packaging that involves plastic pouching, bottle and tube filling, blending, and all kinds of filling.

Rigid Bottle Filling: This is the packaging of bottles with powder, solid, and liquid, which is followed by capping, lot coding, and pack-outs.

Turnkey Product Packager: This is the type of contract packaging that handles the entire process from flexible packaging design, product branding, packaging, storage, and distribution.

3rd Party Logistics: This is another form of turnkey packaging that also involves the dropship, reverse logistics, warehousing, bulk logistics as well as pick and pack.

Conclusion

Contract packaging is one of the fastest-growing practices in manufacturing that has been changing the industry bit by bit. It is especially popular with new manufacturers who are still trying to get their way around, and they may lack the resources to handle the whole process on their own.

For more information on how contract and flexible packaging works, visit our website and have all your questions and concerns answered.